Fitting equipment

LP2 Solutions is pleased to introduce our latest product offering – all of the equipment, tooling, and fixtures necessary to fabricate two piece machined fitting covers. We’ve utilized our principals’ forty years experience in the industrial insulation industry to design and manufacture a compact, industrial grade, portable workstation, ready to plug and play in your facility in a matter of minutes.

The workstation uses 120 V AC, converted to DC to power the variable speed drive motor used in all machining/grinding operations. This machine is capable of machining all of the various rigid insulation materials commonly used in the industrial insulation industry, including cellular glass, ISO, XPS, mineral wool, and fiberglass.

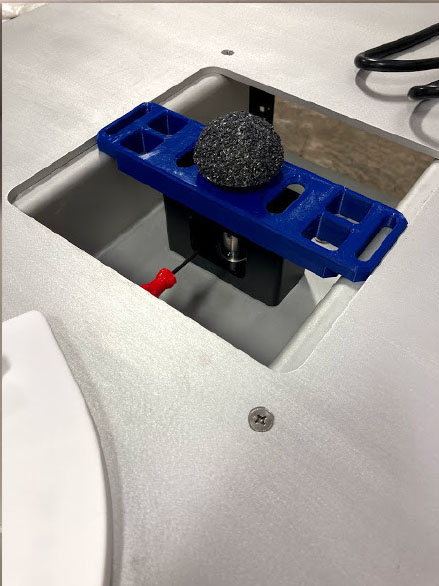

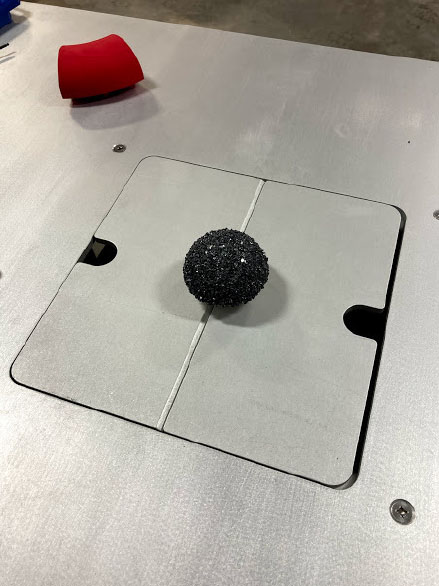

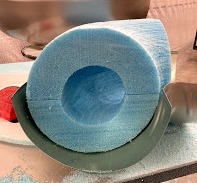

At the heart of this system are all of the various grinding rocks for the inner and outer diameters. This tooling has been designed using modern CAD software and then 3D printed – all to ASTM dimensional standards. Light weight and durable, with stainless steel drive shafts and silicon carbide grit, this tooling makes the grinding operation fast and accurate.

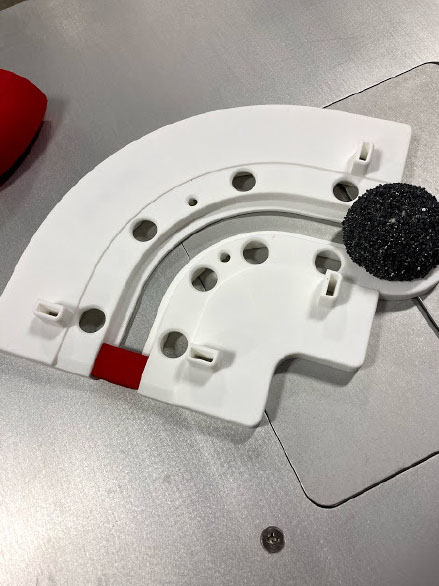

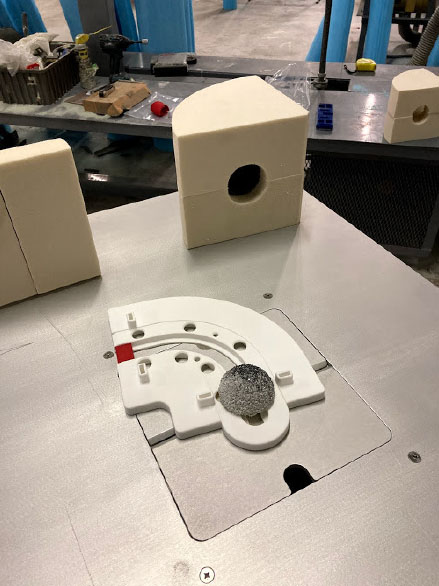

All of the fixtures necessary to convert a raw billet into a finished fitting have also been 3D printed.

ID rocks are available for Iron Pipe Sizes (IPS) 3/4” thru 4”

OD rocks are available for insulation outer diameters (ODs) 2.875 – 10.75 in accordance with ASTM C-585

The current availability of fixtures now totals 70 for the following size 90 degree elbows.

- Long radius welded 90’s – ½” IPS – 1 ½” IPS and in thicknesses from 1” through 2” – 15 sizes total

- Short radius welded 90’s – ½” IPS – 1 ½” IPS and in thicknesses from 1” through 2” – 15 sizes total

- 3000 # socket weld 90’s – ½” IPS – 1 ½” IPS and in thicknesses from 1” through 2” – 15 sizes total

- Long radius welded 90’s – 2” IPS – 4” IPS and insulation thickness from 1” – 3” – 25 sizes total

Additional fixture offering will be coming soon and are likely to include

- Socket weld fittings up through 4” IPS

- 45 degree but weld fittings up through 4” IPS

- Welded Tee’s up through 4” IPS

Larger ID’s and OD’s would be possible using this same workstation, however at some point the tradeoff in material cost to machine compared with mitering pipecover to make fittings becomes an issue.

Our fittings will not only fit the pipe fitting, but will very likely fit inside the jacketing cover, metal or PVC as well.

All of the small IPS ½” – 1 ½” are designed using LP2 Solutions Universal Billets 2.88” – 6.63” OD, all of which are designed to accommodate a negative throat, maintain insulation thickness, and includes an extension beyond the fitting tangent to make for fast, easy installation.

Shown above are four possible fitting which utilize the 5.00 Universal Billet – ¾” x 2” and 1 ½” x 1” – long radius and 3000 # socket weld fitting – short radius 90’s would also fit as will all sizes of ½” x 2” and 2 ½” x 1”