Are there holes in your fab shop, other than in your pipecover?

With our 40 years of experience in waste and cost management, along side our Mulligan Method, we can help put real money back into your margins.

Let us show you what we've learned.

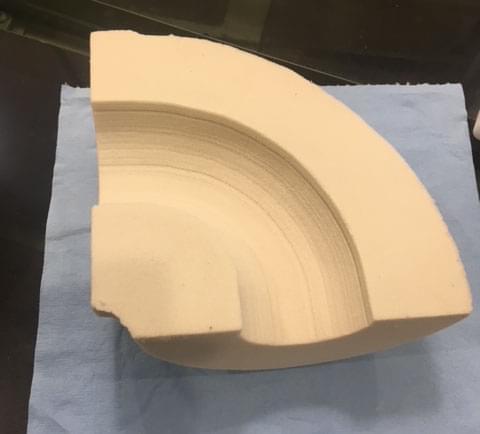

During the past Forty Years, I’ve been making square things round, and flat things curved. I’ve learned the equation for making pipe covering is much simpler than the complex equations dealing with heat loss we learned studying Mechanical Engineering at Carnegie Mellon. Build a billet, cut a piece of pipe cover, and sometimes put a residual core into inventory for use at a late time.

This all appears to be pretty simple and straight forward – we focus on the material used, a Foamglas billet of some shape (could be square or if we are cleaver, a trapezoid or combination of trapezoids), and then we cut the pipe cover round with a hole in the middle, and typically have a core left over. All this is utilizing our Mulligan Method with our specially designed fitting equipment, and we turn your fabrication process into a lean, mean, pipe fitting machine.

We can not only help with the process above, streamlining your fabrication process, but we will also be able to assist in everything from the loading dock, to the front office and board room. Contact us today to start a conversation about how we can help